Dehydrated Onion

Dehydrated onion is fresh onion that has been dehydrated for easier storage and use. It has a wide range of uses, including as a seasoning, ready-to-eat food, and processed material.

WINGEN GROUP is a professional Dehydrated onion manufacturer in China. If you have any needs for this product, please be sure to contact us at info@wingengroup.com and we will respond to you within 12 hours.

Specification available: 100%

CAS No.: /

MOQ: 1 Ton

BRAND: WINGEN

Introduction of Dehydrated Onion

Dehydrated Onion is a processed form of onion where the moisture content is removed, leaving behind a lightweight, shelf-stable product that retains the flavor, aroma, and nutritional properties of fresh onions. It is a convenient and versatile ingredient widely used in food preparation and manufacturing.

Key Features of Dehydrated Onion

Moisture Removal:

The water content is removed through drying methods such as hot air drying, freeze-drying, or sun drying, resulting in a product with a significantly reduced weight and volume.

Forms Available:

Dehydrated onions come in various forms, including:

- Flakes: Thin, flat pieces of onion.

- Chopped: Small, diced pieces.

- Powder: Finely ground onion.

- Granules: Small, coarse particles.

- Minced: Finely cut pieces.

Flavor Retention:

The dehydration process preserves the natural flavor and aroma of onions, making it a great alternative to fresh onions in many recipes.

Long Shelf Life:

Due to the removal of moisture, dehydrated onions have a much longer shelf life compared to fresh onions, making them ideal for storage and transportation.

Convenience:

Dehydrated onions are ready to use, eliminating the need for peeling, chopping, or cleaning fresh onions. They can be rehydrated or used directly in cooking.

Uses of Dehydrated Onion

Dehydrated onion is versatile and widely used in various culinary and food processing applications. Some common uses include:

1. Seasoning and Spices

It’s often used in spice blends, sauces, and marinades for added flavor without the need for fresh onions.

2. Soups and Stews

A convenient addition to soups, stews, and broths for a rich onion flavor.

3. Snack Foods

Used in chips, dips, and seasoning for snacks like popcorn or crackers.

4. Ready-to-Eat Meals

Often found in instant noodles, frozen meals, or other convenience foods.

5. Baking

It can be incorporated into savory baked goods like bread, crackers, and biscuits.

6. Condiments

Used in ketchup, mustard, or salad dressings for enhanced flavor.

Why Choose Dehydrated Onion?

Choosing Dehydrated onion offers several advantages:

1. Long Shelf Life

It can be stored for months or even years without spoiling, making it ideal for bulk storage and reducing waste.

2. Convenience

It’s easy to use without the need for peeling, chopping, or refrigeration, saving time in food preparation.

3. Consistent Flavor

Dehydrated onion provides a consistent and concentrated flavor, which is perfect for commercial food production or home cooking.

4. Nutrient Retention

It retains most of the nutrients from fresh onion, such as vitamins and minerals, even after dehydration.

5. Space-Saving

It’s lightweight and compact, making it easy to store and transport.

Dehydrated onion is a practical, versatile, and cost-effective option for many culinary applications. If you would like more information please contact us.

Manufacturer Introduction of Dehydrated Onion

WINGEN GROUP LIMITED is an independent R&D center and modern factory. We have planting bases are located in Anhui and Yunnan, while we have a R&D center in Yunnan and Shanghai with modern production technology and clean workshops. At the same time, we have a variety of utility model patents and trademarks.

Advantages of our company(WINGEN GROUP LIMITED)

- 1. Efficient production technology to ensure high purity and high concentration of extracts.

- 2. Strict quality control to ensure product stability and consistency.

- 3. R&D and innovation capabilities to provide customized formulas and new product development.

- 4. Traceable raw material supply to ensure safety and environmental protection.

- 5. Global market coverage, widely used in health care products, cosmetics and other industries.

Production Shop Display

Our (WINGEN GROUP LIMITED) Dehydrated onion production workshop is strictly managed in accordance with GMP and international quality standards, equipped with advanced equipment and technology to ensure efficient production.

The workshop environment is clean and meets hygiene standards, and the production process is compliant and traceable.

Employees are professionally trained and operate in accordance with standard procedures to ensure the high quality and safety of the products.

These measures make the workshop production regular and efficient, and can meet customer needs.

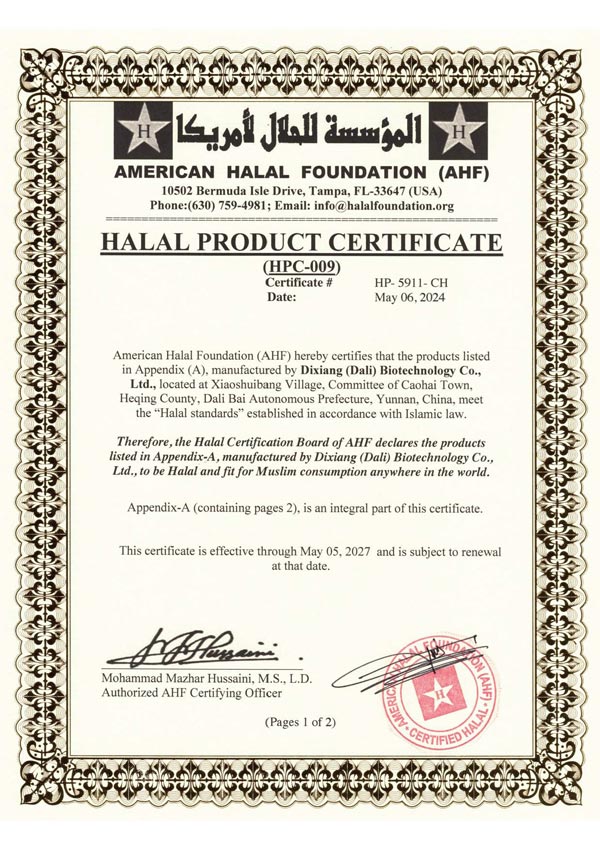

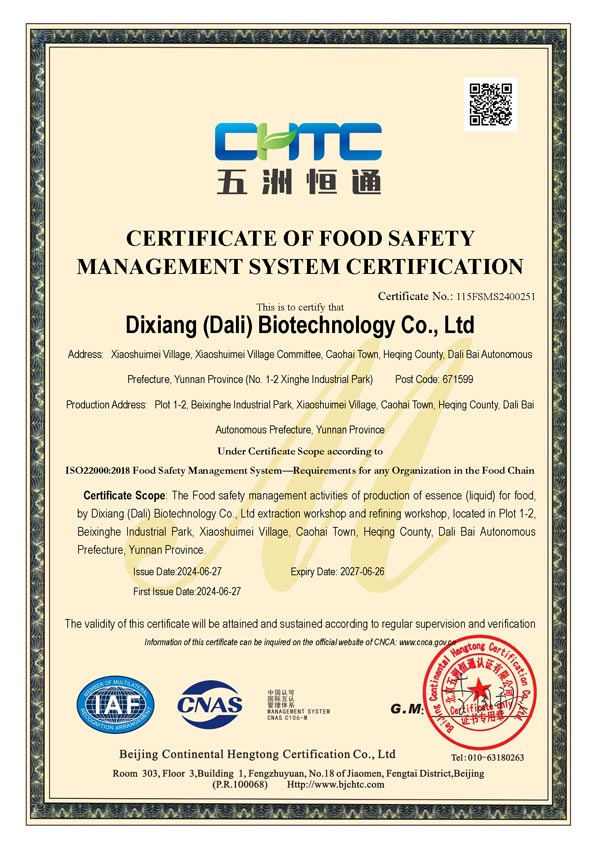

Certificate Display

The following are our certificates, including ISO 9001 (Quality Management System Certification), ISO 22000 (Food Safety Management System Certification) and HALAL certificates, which ensure that the products we provide meet international standards. These certifications prove that our production processes and quality control measures meet the highest industry standards, thus ensuring the quality and safety of our products.

Contact Details

WINGEN GROUP LIMITED

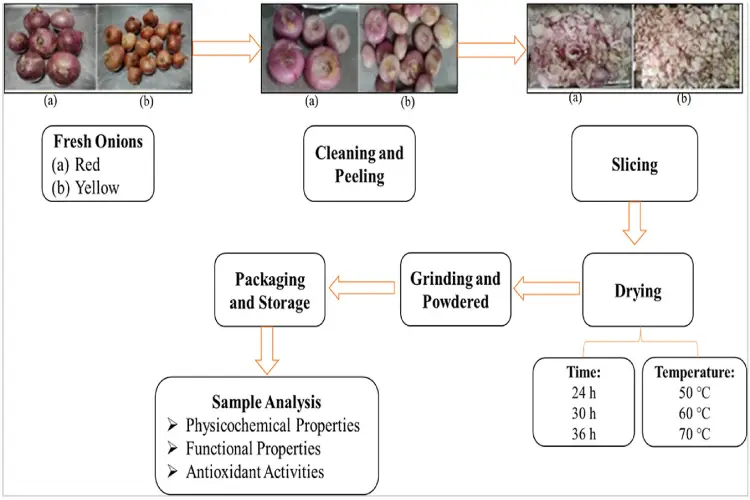

Production process of Dehydrated onion

The production process of dehydrated onion typically involves the following steps:

1. Selection and Cleaning: Fresh onions are carefully selected and cleaned to remove dirt, skins, and any damaged parts.

2. Peeling and Slicing: The onions are peeled, then sliced or chopped into desired sizes, such as flakes, rings, or powder.

3. Blanching (Optional): Some producers blanch the onion by briefly dipping it in boiling water, which helps preserve color and flavor and reduce microbial contamination.

4. Drying: The sliced onions are then dried using methods such as:

- Air Drying: Using warm, dry air to remove moisture.

- Freeze Drying: Freezing the onions and then removing the moisture through sublimation.

- Hot Air Drying: Using heated air to speed up the drying process.

5. Grinding or Cutting: Once dried, the onion can be ground into powder or kept in flakes or granules, depending on the intended use.

6. Packaging: The dehydrated onion is packaged in moisture-proof containers to maintain its freshness and shelf life.

Precautions for Factories Using Dehydrated Onion

When factories use dehydrated onion, there are a few important precautions to ensure quality and safety:

1. Proper Storage

Store dehydrated onion in a cool, dry place, away from direct sunlight and moisture to prevent spoilage or clumping.

2. Hygiene Standards

Maintain strict cleanliness during handling to avoid contamination, as onions are prone to bacteria growth if improperly stored.

3. Moisture Control

Ensure proper sealing of storage containers to prevent moisture absorption, which could lead to mold or spoilage.

4. Quality Control

Regularly check the quality of the dehydrated onion, including flavor, texture, and color, to ensure consistency in the final product.

5. Rehydration Process

If rehydrating the onion, follow the correct ratio of water to prevent over-soaking, which can affect texture and flavor.

6. Allergen Awareness

Onions can sometimes cause allergic reactions in sensitive individuals, so proper labeling and precautions are important.

These measures help maintain the quality and safety of dehydrated onion in food manufacturing.

More Product Recommendations

In addition to Dehydrated onion,we can also provide you with many other related products, if you want to know more information, please feel free to contact us, looking forward to your message.

Dehydrated Products

Flower and Herb Essential Oils

Herbal Extract